THE MAKING PROCESS OF F.PROKOP JEWELLERY

– THE PROJECT –

It all starts with the design. After consultation with the client and arrangement, the jewellery vision is to prepare a design, select stones, material, and color of the gold.

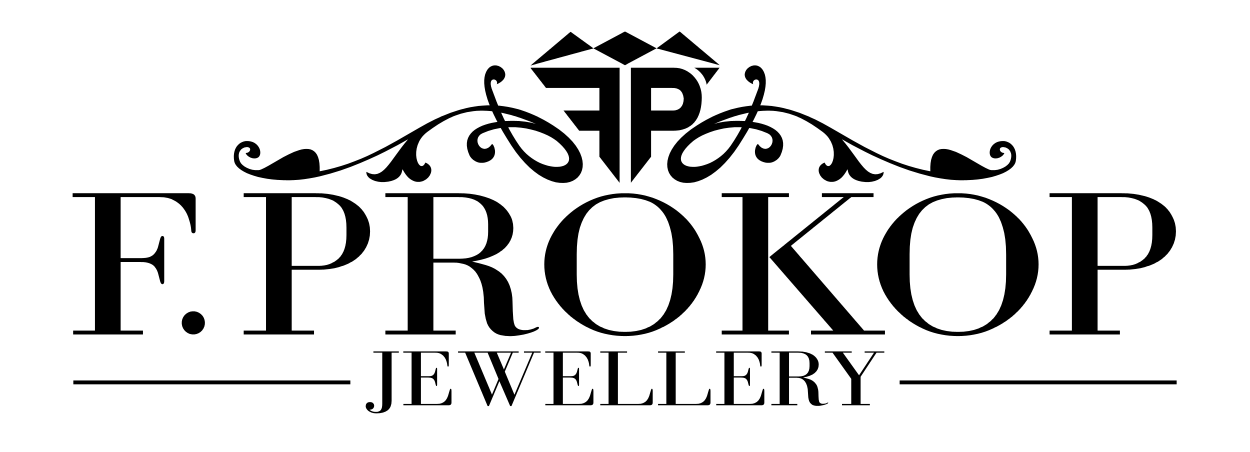

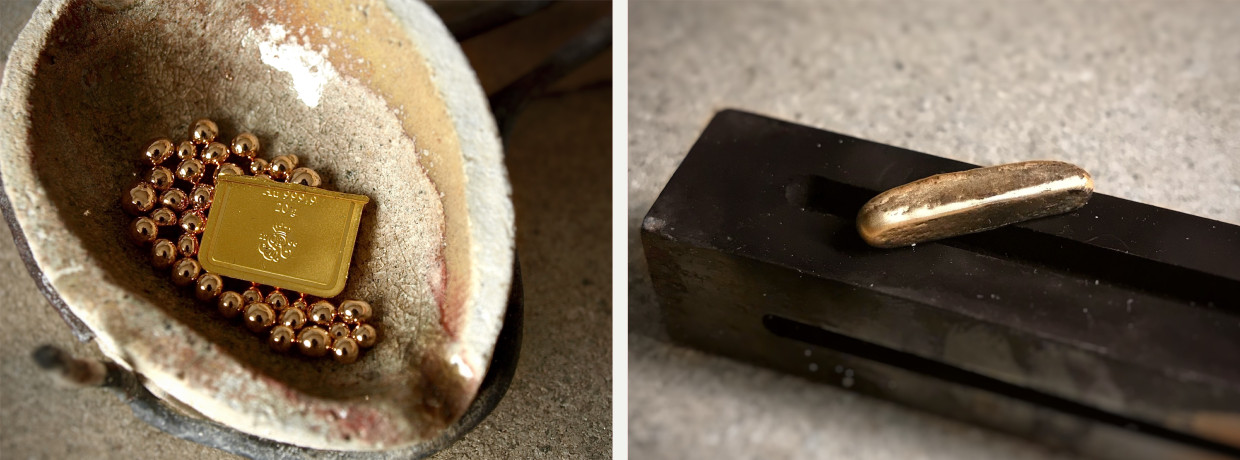

– PREPARING THE METAL –

After selecting the appropriate alloying additives, the prepared material is melted in the crucible using a blow torch, which is then poured into a ingot mould.

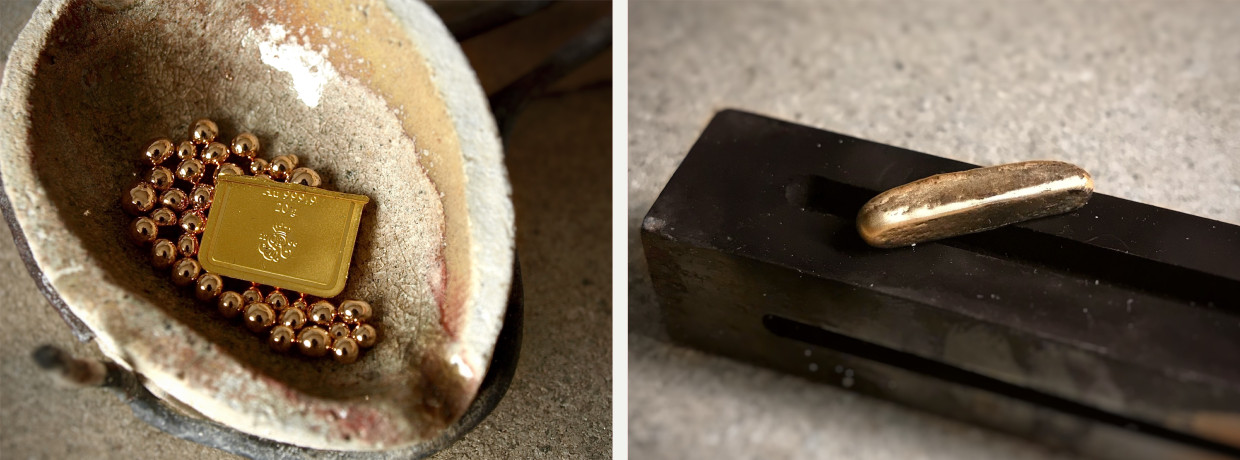

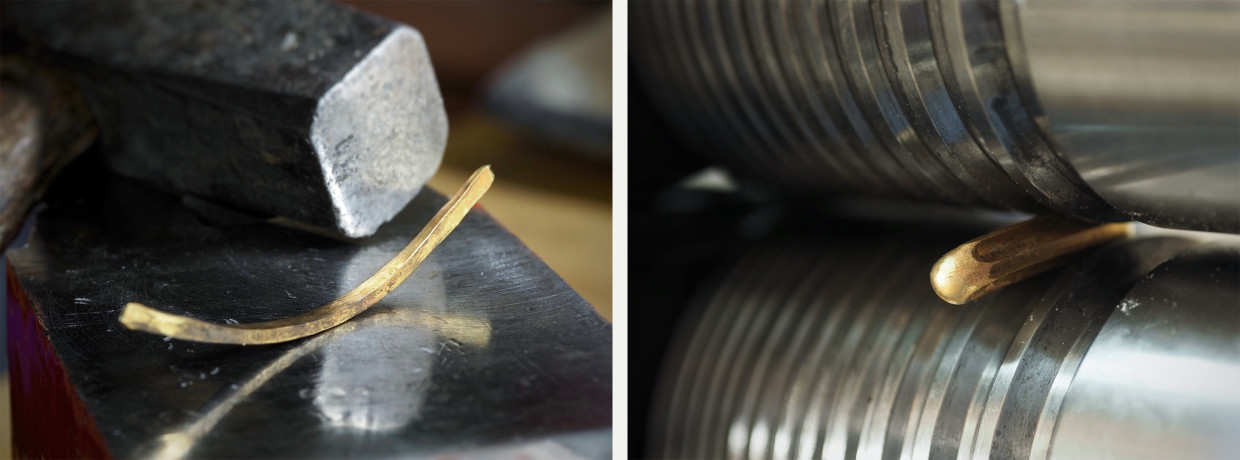

– FORMING AND PLANISHING –

The casted material is rolled on a jewellery rolling mill, processed by metalworking methods to give the desired shapes or pulled in a draw plate to form a wire.

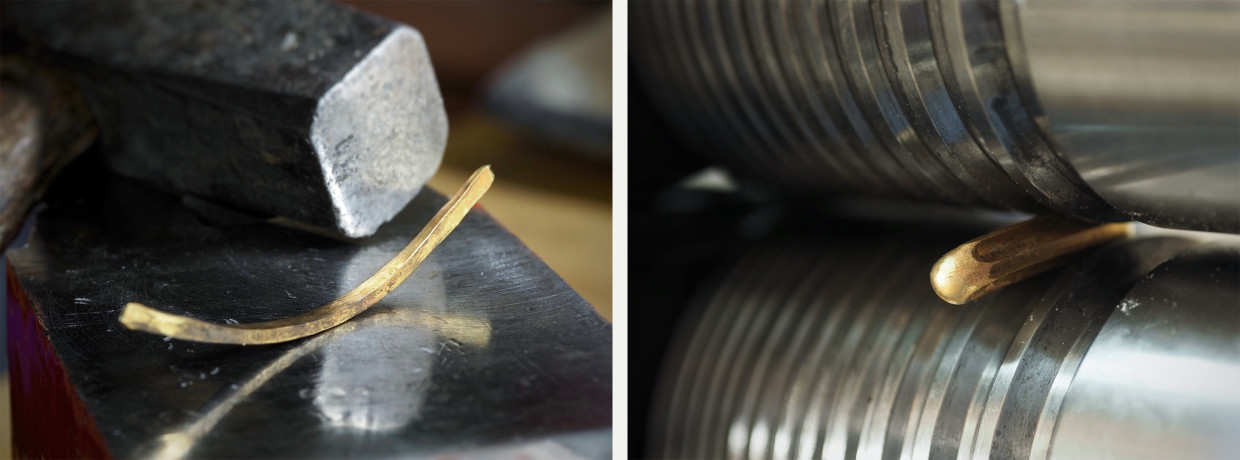

– SAWING AND SOLDERING –

Preparing the rest of the pieces by modeling, cutting with a saw blade, processing files, burrs and gravers, then assemble them and solder them with a blow torch.

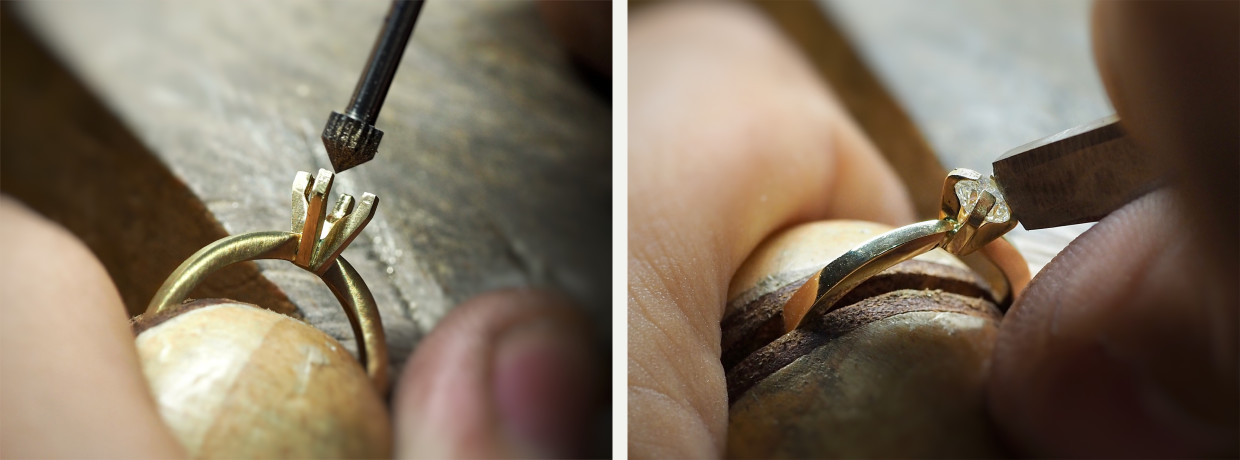

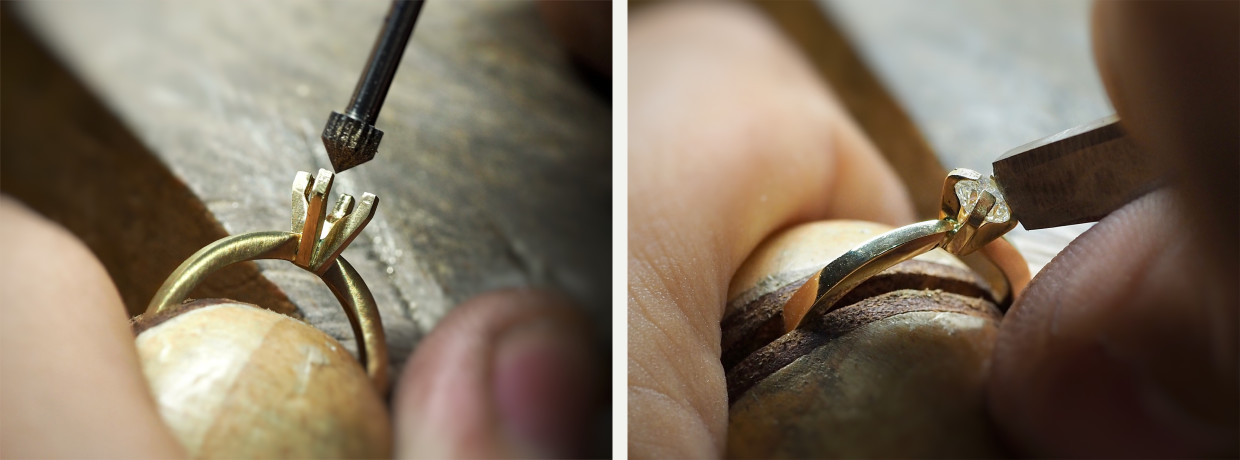

– STONE SETTING –

Depending on the type of the setting, holes are drilled for the stones, the setting is prepared with the use of jewellery burrs and gravers, and then the stones are inserted, which are secured by bending a part of the metal on them.

– POLISHING AND TEXTURING –

The prepared product or elements before soldering are polished with a polishing paste to a high gloss and depending on the design, it is given the appropriate texture by satining, hammering, etc.

– THE FINAL PRODUCT –

Traditional handicraft, gives the jewelry a very personal character and makes it a one of its kind product.

THE MAKING PROCESS OF F.PROKOP JEWELLERY

– THE PROJECT –

It all starts with the design. After consultation with the client and arrangement, the jewellery vision is to prepare a design, select stones, material, and color of the gold.

– PREPARING THE METAL –

After selecting the appropriate alloying additives, the prepared material is melted in the crucible using a blow torch, which is then poured into a ingot mould.

– FORMING AND PLANISHING –

The casted material is rolled on a jewellery rolling mill, processed by metalworking methods to give the desired shapes or pulled in a draw plate to form a wire.

– SAWING AND SOLDERING –

Preparing the rest of the pieces by modeling, cutting with a saw blade, processing files, burrs and gravers, then assemble them and solder them with a blow torch.

– STONE SETTING –

Depending on the type of the setting, holes are drilled for the stones, the setting is prepared with the use of jewellery burrs and gravers, and then the stones are inserted, which are secured by bending a part of the metal on them.

– POLISHING AND TEXTURING –

The prepared product or elements before soldering are polished with a polishing paste to a high gloss and depending on the design, it is given the appropriate texture by satining, hammering, etc.

– THE FINAL PRODUCT –

Traditional handicraft, gives the jewelry a very personal character and makes it a one of its kind product.